How does a spherical roller bearing work?

A spherical roller bearing is a self-aligning bearing that can adapt to the bending and angular deviation of the shaft, thereby providing stability and reliability in various industrial applications. The following is a detailed explanation of the working principle of a spherical roller bearing:

Structural composition

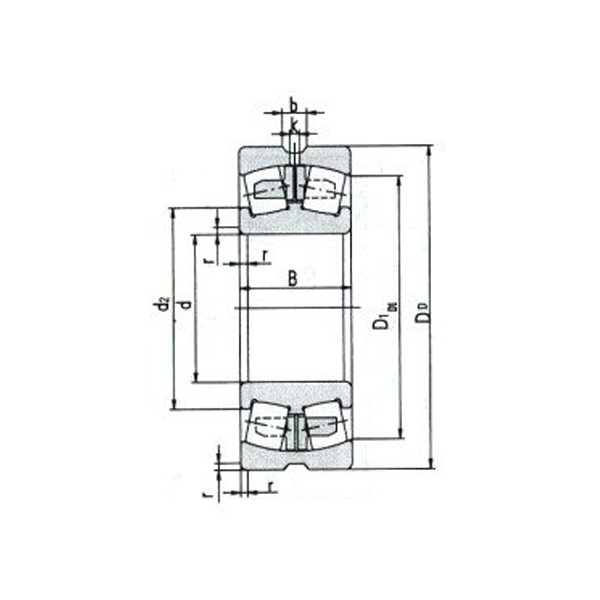

Spherical roller bearings are mainly composed of the following parts:

Inner ring: Fits with the shaft and is usually fixed to the shaft by an interference fit.

Outer ring: Fits with the bearing seat and is usually fixed to the bearing seat by an interference fit or a tight sleeve.

Rolling element: Rolls between the inner and outer rings, which can be balls or rollers. Spherical roller bearings use rollers.

Cage: Used to evenly separate the rolling elements, prevent them from contacting each other, and reduce friction.

Working principle

Self-aligning ability: The rolling elements (rollers) of spherical roller bearings are designed with an asymmetric shape, which is wider at both ends and narrower in the middle. This design allows the rollers to move freely between the inner and outer rings to adapt to the bending or angular deviation of the shaft.

Load distribution: When the bearing is under load, the rollers automatically adjust their positions according to the size and direction of the load to achieve a more even load distribution. This helps reduce local stress and wear.

Rolling element contact with the raceway: The rollers roll on the raceways of the inner and outer rings, and the geometry of the raceways is designed to match the shape of the rollers to achieve optimal rolling performance.

Role of the cage: The cage not only separates the rollers, but also guides the rollers to the correct position within the bearing, ensuring the stability of the rollers during rolling.

Lubrication: Lubrication of spherical roller bearings is essential to reduce friction and wear. Grease or oil is usually used to lubricate the bearing to maintain operating efficiency and extend the life.

Sealing: The sealing system of the bearing prevents contaminants from entering the interior of the bearing while keeping the lubricant inside the bearing, which is essential for the long-term operation of the bearing.

Application scenarios

Due to their self-aligning characteristics, spherical roller bearings are particularly suitable for applications where the shaft may bend or angularly deviate, such as:

Vibrating screens: In vibrating screens, the bearings need to withstand the vibrations generated by the screening materials.

Crusher: Crusher generates strong shock and vibration when working, and spherical roller bearings can adapt to these conditions.

Vibrating feeder: During the feeding process, the bearing needs to withstand the impact and vibration of the material.

Maintenance of spherical roller bearings includes regular inspection of lubrication conditions, cleaning of bearing seats and replacement of worn parts. Proper maintenance can significantly extend the service life of the bearings.

Spherical roller bearings are designed to perform well in applications subject to high loads and vibrations. Through their self-aligning ability, load distribution, contact between rolling elements and raceways, the role of cages, and good lubrication and sealing, spherical roller bearings can provide stable and reliable performance in a variety of industrial environments.

Why are spherical roller bearings needed in vibrating applications?

The reason for using spherical roller bearings in vibrating applications is mainly due to their unique design characteristics and performance advantages in high vibration environments. Here is a detailed explanation:

Vibrating applications, such as vibrating screens, crushers, vibrating feeders, etc., usually generate continuous vibrations during operation. These vibrations may cause bending or angular deviation of the shaft, affecting the normal operation of the equipment. The self-aligning ability of spherical roller bearings allows them to adapt to these changes and keep the equipment running smoothly.

Spherical roller bearings are designed to carry high loads, including radial loads and bidirectional axial loads. This load-carrying capacity is particularly important in vibrating applications, as vibration can increase stress and wear on the bearing.

The rollers of spherical roller bearings are designed with an asymmetrical shape, wider at the ends and narrower in the middle. This design allows the rollers to move freely between the inner and outer rings, automatically adjusting to shaft bending or angular deviations and reducing additional stress caused by vibration.

Because spherical roller bearings can automatically adjust to shaft deviations, they are able to reduce wear caused by vibration. This ability to reduce wear helps extend the service life of the bearing and the entire equipment.

The rollers of spherical roller bearings can automatically adjust their position according to the size and direction of the load, achieving a more even load distribution. This optimized load distribution helps reduce local stress and wear, and improves the durability of the bearing.

The cage plays a vital role in spherical roller bearings. It not only separates the rollers, preventing them from contacting each other and reducing friction, but also guides the rollers to the correct position in the bearing, ensuring the stability of the rollers during rolling.

Lubrication of spherical roller bearings is essential to reduce friction and wear. Grease or oil is usually used for lubrication to maintain the operating efficiency and extend the life of the bearing. In addition, the sealing design of the bearing prevents contaminants from entering and protects the bearing from damage.

Although the design of spherical roller bearings is complex, their maintenance is relatively simple. Regular inspection and maintenance can ensure the performance and life of the bearing.

Although the initial cost of spherical roller bearings may be high, their long life and low maintenance requirements can reduce overall operating costs.

The self-aligning characteristics of spherical roller bearings enable them to adapt to a variety of different working environments and conditions, including harsh environments such as high temperature, high humidity, and pollution.

In summary, the use of spherical roller bearings in vibrating applications is due to their ability to provide stability, reduce wear, optimize load distribution, maintain high efficiency, and extend equipment life. These characteristics make them an ideal choice for equipment such as vibrating screens, crushers, and vibrating feeders.

What role does the spherical roller bearing play in the vibrating screen?

The vibrating screen is a device that uses the principle of vibration to grade or screen materials. The spherical roller bearing plays a vital role in the vibrating screen:

Withstand vibration load: The vibrating screen will generate strong vibrations when working, and the spherical roller bearings can withstand these vibration loads to ensure the stable operation of the screening machine.

Reduce the wear of the screening machine: Due to the self-aligning ability of the spherical roller bearing, the shaft bending or angle deviation caused by vibration can be reduced, thereby reducing the wear of the screening machine.

Improve screening efficiency: The spherical roller bearings can ensure the stability of the screening machine in a high vibration environment, thereby improving the screening efficiency.

Extend the service life of the screening machine: By reducing wear and improving stability, the spherical roller bearings can extend the service life of the screening machine.

Reduce maintenance costs: The high durability and reliability of the spherical roller bearings can reduce the maintenance costs of the screening machine.

Improve the reliability of the screening machine: The spherical roller bearings can improve the reliability of the screening machine under various working conditions and reduce the downtime caused by bearing failure.

Adapt to different working environments: The design of spherical roller bearings enables them to adapt to different working environments, including harsh conditions such as high temperature and high humidity.

Improve the flexibility of the screening machine: Due to the self-aligning ability of the spherical roller bearings, the screening machine can maintain efficient operation under different working conditions and improve its flexibility.

Reduce the noise of the screening machine: The smooth operation of the spherical roller bearings can reduce the noise generated by the screening machine during operation and improve the working environment.

Improve the safety of the screening machine: The high reliability and stability of the spherical roller bearings can improve the safety of the screening machine and reduce safety accidents caused by bearing failures.

Search

Search EN

EN English

English Español

Español