| Basic dimensions | Basic load rating (KN) |

Limiting speed (r/min) |

Bearing number | Dimentions | Abutment and fillet dimensions (mm) |

Mass kg |

||||||||||||||

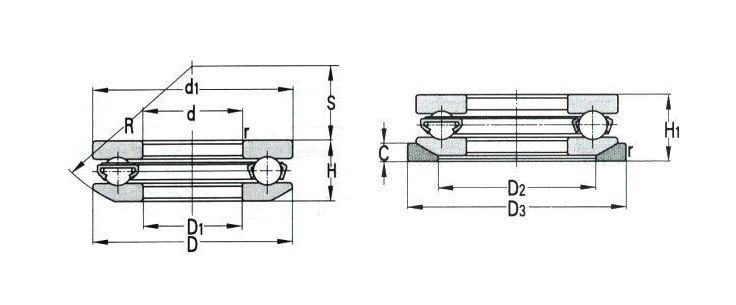

| d(mm) | D(mm) | rmin | Cr | Cor | Grease | Oil | d1 | D1 | D2 | D3 | C | H1 | R | S | H | da(min) | Da(max) | ra(max) | ||

| 30 | 52 | 0.6 | 26.6 | 39.9 | 3600 | 4800 | 53206+U206 | 52 | 32 | 42 | 55 | 5.5 | 20 | 45 | 22 | 17.8 | 43 | 42 | 0.6 | 0.180 |

| 35 | 62 | 1 | 37.3 | 55.5 | 3000 | 4000 | 53207+U207 | 62 | 37 | 48 | 65 | 7 | 22 | 50 | 24 | 19.9 | 51 | 48 | 1 | 0.263 |

| 40 | 68 | 1 | 46.9 | 78.4 | 2800 | 3800 | 53208+U208 | 68 | 42 | 55 | 72 | 7 | 23 | 56 | 28.5 | 20.3 | 57 | 55 | 1 | 0.395 |

| 45 | 73 | 1 | 47.7 | 81.3 | 2600 | 3600 | 53209+U209 | 73 | 47 | 60 | 78 | 7.5 | 24 | 56 | 26 | 21.3 | 62 | 60 | 1 | 0.400 |

| 50 | 110 | 1.5 | 159 | 197 | - | - | 53410M | 110 | 52 | - | - | - | - | 90 | 35 | 45.6 | - | - | - | 1.92 |

| 55 | 90 | 1 | 69 | 123 | 1900 | 2800 | 53211+U211 | 90 | 57 | 72 | 95 | 9 | 30 | 72 | 35 | 27.3 | 76 | 72 | 1 | 0.747 |

| 60 | 110 | 1 | 130 | 208 | - | - | 53312 | 110 | 62 | - | - | - | - | 90 | 41 | 38.3 | - | - | - | 1.44 |

| 65 | 100 | 1 | 74.9 | 151 | 1800 | 2600 | 53213+U213 | 100 | 67 | 82 | 105 | 9 | 32 | 80 | 40 | 28.5 | 86 | 82 | 1 | 0.898 |

| 70 | 130 | 1.1 | 148 | 250.6 | 1400 | 1900 | 53314+U314 | 125 | 72 | 98 | 130 | 13 | 48 | 100 | 43 | 44.2 | 103 | 98 | 1 | 2.51 |

| 70 | 125 | 1.1 | 148 | 250.6 | - | - | 53314 | 125 | 72 | - | - | - | - | 100 | 43 | 44.2 | - | - | - | 2.10 |

| 70 | 105 | 1 | 59 | 161 | 1800 | 2600 | 53214+U214 | 105 | 72 | 88 | 110 | 9 | 32 | 80 | 38 | 28.8 | 91 | 88 | 1 | 0.961 |

| 75 | 110 | 1 | 82.1 | 172.7 | 1700 | 2400 | 53215+U215 | 110 | 77 | 92 | 115 | 9.5 | 32 | 90 | 49 | 28.2 | 96 | 92 | 1 | 1.15 |

| 80 | 115 | 1 | 86.6 | 193.2 | 1700 | 2400 | 53216+U216 | 115 | 82 | 98 | 120 | 10 | 33 | 90 | 46 | 29.5 | 101 | 98 | 1 | 1.18 |

| 80 | 145 | 1.5 | 181 | 315 | 1200 | 1700 | 53316+U316 | 140 | 82 | 110 | 145 | 15 | 52 | 112 | 50 | 47.6 | 116 | 110 | 1.5 | 3.17 |

| 85 | 180 | 1.1 | 336 | 534 | - | - | 53417M | 177 | 88 | - | - | - | - | 140 | 47 | 77 | - | - | - | 8.95 |

| 90 | 135 | 1.1 | 133 | 285 | 1500 | 2000 | 53218+U218 | 135 | 93 | 110 | 140 | 13.5 | 42 | 100 | 45 | 38.5 | 117 | 110 | 1 | 2.33 |

| 100 | 170 | 1.5 | 282 | 498 | 950 | 1400 | 53320+U320 | 170 | 103 | 135 | 175 | 18 | 64 | 125 | 46 | 59.2 | 142 | 135 | 1.5 | 5.83 |

| 100 | 170 | 1.5 | 282 | 498 | - | - | 53320 | 170 | 103 | - | - | - | - | 125 | 46 | 59.2 | - | - | - | 4.90 |

| 100 | 205 | 3 | 448 | 775 | 700 | 950 | 53420M+U420 | 205 | 103 | 155 | 220 | 27 | 98 | 160 | 50 | 90 | 165 | 155 | 2.5 | 16.5 |

| 100 | 205 | 3 | 421 | 734.5 | 700 | 950 | 53420+U420 | 205 | 103 | 155 | 220 | 27 | 98 | 160 | 50 | 90 | 165 | 155 | - | 16.2 |

| 110 | 160 | 1.1 | 170 | 392.5 | 1200 | 1700 | 53222+U222 | 160 | 113 | 135 | 165 | 14 | 45 | 125 | 65 | 40.2 | 140 | 135 | 1 | 2.87 |

| 110 | 190 | 2 | 304 | 588 | 850 | 1200 | 53322M+U322 | 187 | 113 | 150 | 195 | 20.5 | 72 | 140 | 51 | 67.2 | 158 | 150 | 2 | 9.05 |

| 110 | 190 | 2 | 304 | 588 | 850 | 1200 | 53322+U322 | 187 | 113 | 150 | 195 | 20.5 | 72 | 140 | 51 | 67.2 | 158 | 150 | 2 | 8.78 |

| 120 | 170 | 1.1 | 168 | 399 | 1100 | 1600 | 53224+U224 | 170 | 123 | 145 | 175 | 15 | 46 | 125 | 61 | 40.8 | 150 | 145 | 1 | 3.07 |

| Basic dimensions | Basic load rating (KN) |

Limiting speed (r/min) |

Bearing number | Dimentions | Abutment and fillet dimensions (mm) |

Mass kg |

||||||||||||||

| d(mm) | D(mm) | rmin | Cr | Cor | Grease | Oil | d1 | D1 | D2 | D3 | C | H1 | R | S | H | da(min) | Da(max) | ra(max) | ||

| 120 | 205 | 2.1 | 129 | 400 | 800 | 1100 | 53324M+U324 | 205 | 123 | 165 | 220 | 22 | 80 | 160 | 63 | 74.1 | 173 | 165 | 2 | 12.3 |

| 120 | 205 | 2.1 | 129 | 400 | 800 | 1100 | 53324+U324 | 205 | 123 | 165 | 220 | 22 | 80 | 160 | 63 | 74.1 | 173 | 165 | 2 | 11.9 |

| 120 | 205 | 2.1 | 129 | 400 | 800 | 1100 | 53324/YB2+U324 | 205 | 123 | 165 | 220 | 22 | 80 | 160 | 63 | 74.1 | 173 | 165 | 2 | 11.9 |

| 120 | 205 | 2.1 | 129 | 400 | 800 | 1100 | 53324U/YB2-1 | 205 | 123 | 165 | 220 | 22 | 80 | 160 | 63 | 74.1 | 173 | 165 | 2 | 11.9 |

| 130 | 265 | 4 | 637 | 1284 | - | - | 53426M+U426 | 265 | 134 | 200 | 280 | 38 | 128 | 200 | 58 | 115.2 | - | - | - | 34.8 |

| 130 | 265 | 4 | 637 | 1284 | - | - | 53426+U426 | 265 | 134 | 200 | 280 | 38 | 128 | 200 | 58 | 115.2 | - | - | - | 34.6 |

| 150 | 250 | 2.1 | 429 | 1021 | - | - | 53330M+U330 | 245 | 154 | 200 | 260 | 26 | 92 | 200 | 89.5 | 83.7 | - | - | - | 19.5 |

| 150 | 250 | 2.1 | 429 | 1021 | - | - | 53330+U330 | 245 | 154 | 200 | 260 | 26 | 92 | 200 | 89.5 | 83.7 | - | - | - | 18.0 |

| 150 | 250 | 2.1 | 429 | 1021 | - | - | 53330/YB2+U330 | 245 | 154 | 200 | 260 | 26 | 92 | 200 | 89.5 | 83.7 | - | - | - | 18.6 |

| 150 | 250 | 2.1 | 429 | 1021 | - | - | 53330 | 245 | 154 | - | - | - | - | 200 | 89.5 | 83.7 | - | - | - | 15.1 |

| 150 | 295 | 4 | 673 | 1479 | - | - | 53430M+U430 | 295 | 154 | 225 | 310 | 41 | 140 | 225 | 69 | 125.9 | - | - | - | 44.1 |

| 220 | 297 | 2 | 366 | 1148 | - | - | 53244+U224 | 297 | 224 | 260 | 310 | 25 | 75 | 225 | 118 | 65.6 | - | - | - | 15.6 |

| 300 | 375 | 2.5 | 382 | 1483 | - | - | - | 375 | 300.3 | 340 | 385 | 17 | 75 | 320 | 202 | 70 | - | - | - | 17.2 |

| 430 | 580 | 3.7 | 922 | 4348 | - | - | - | 580 | 430.5 | 500 | 610 | 45 | 150 | 500 | 301.3 | 131.7 | - | - | - | 129 |

Search

Search EN

EN English

English Español

Español