Cam followers, also known as track followers or track rollers, are specialized bearings designed to follow cams or tracks in various machinery applications. They are typically used in applications where linear motion is required, such as conveyor systems, cam-driven mechanisms, and linear motion systems. The basic structure of a cam follower consists of a stud or shaft with a concentric roller or needle bearing mounted on it. This roller or needle bearing is usually designed to roll along a cam or track profile, transmitting motion smoothly and efficiently.

Material Foundations That Influence Corrosion Resistance in deep groove ball bearings The corrosion and moisture resista...

READ MOREGeneral Considerations for Deep Groove Ball Bearings in Challenging Environments Deep groove ball bearings are widely us...

READ MOREIntroduction to Ball Bearings and Their Durability Ball bearings are mechanical components that facilitate smooth and ef...

READ MOREIntroduction to Deep Groove Ball Bearings Deep groove ball bearings are one of the most widely used types of ball bearin...

READ MOREIn Which Applications Are the Self-Aligning Properties of Self-Aligning Ball Bearings Particularly Advantageous? Self-al...

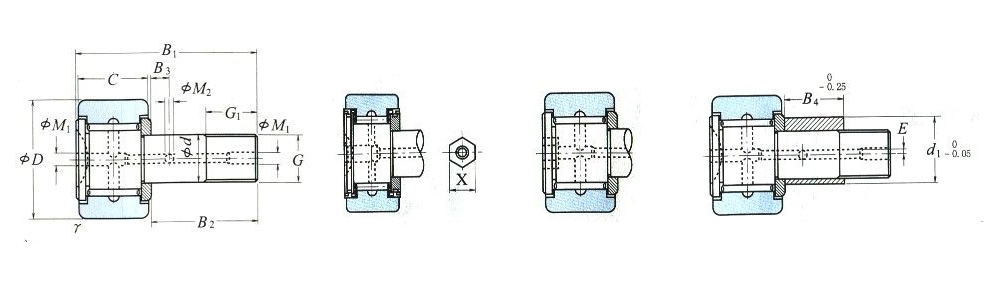

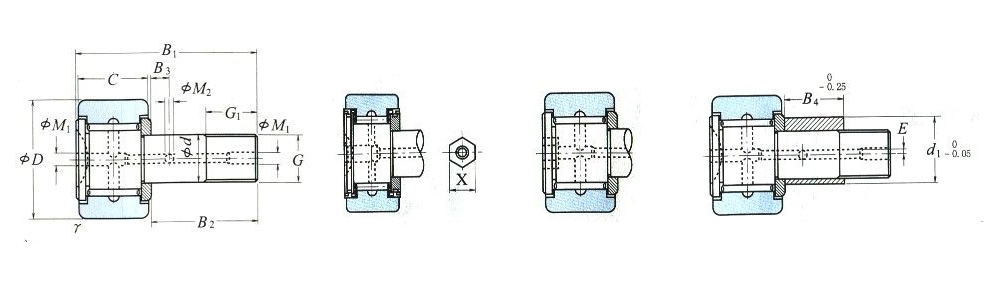

READ MORECam Followers are mainly composed of three main parts: roller, bearing and body. The roller is located at one end of the Cam Followers, and it is in direct contact with the profile of the cam to achieve rolling friction. The bearing is used to support the roller and ensure that it can rotate freely. The main part connects the roller and the bearing, which is usually a cylindrical metal body used to carry and transfer loads.

1. Basic interaction between cam and roller

The working principle of Cam Followers mainly depends on the basic interaction between cam and roller. In mechanical transmission, the cam is usually a rotating part with a specific profile, and the roller is the key part of Cam Followers, which is in direct contact with the profile of the cam. When the cam rotates, its profile pushes the roller to move along a certain trajectory. This push enables the roller to roll smoothly under the guidance of the cam.

2. Roller rolling mechanism

The roller plays a key role in Cam Followers, and its rolling mechanism is the core of realizing motion conversion. Bearings are usually installed inside the roller to ensure that it can rotate freely. When the high point of the cam profile contacts the roller, the roller will rise along the cam profile; when the low point of the cam profile contacts the roller, the roller will fall. This rising and falling movement is transmitted to the main body of the Cam Followers through the roller, which in turn drives the parts connected to it to move linearly or swing.

3. Implementation of motion conversion

Cam Followers realize the conversion of the cam's rotational motion to linear motion or swing through the rolling mechanism of the roller. When the cam rotates, every point on its profile will contact the roller, pushing the roller to move along a specific trajectory. This trajectory is determined by the profile of the cam, so the movement trajectory of the roller can be controlled by designing the profile of the cam. When the roller moves, it will drive the main body of the Cam Followers to move together, thereby realizing the linear motion or swing of the parts connected to the Cam Followers.

4. Internal structure and transmission efficiency

The internal structure of Cam Followers is crucial to the realization of its working principle. The precise matching of the roller and the bearing ensures the smooth rolling and precise transmission of the roller. The main part of Cam Followers is usually made of high-strength, wear-resistant materials to ensure that it can withstand large loads and long-term operation. This structural design and material selection help improve the transmission efficiency and service life of Cam Followers.

5. Detailed analysis during the working process

There are still some details that need to be paid attention to during the working process of Cam Followers. For example, a certain friction will be generated at the contact point between the roller and the cam, which will affect the rolling effect and transmission efficiency of the roller. In order to reduce this friction, appropriate lubrication measures are usually adopted, such as applying lubricating oil or installing lubrication devices. The wear of rollers and bearings will also affect the performance of Cam Followers, so regular inspection and maintenance are required, and severely worn parts should be replaced in time.

The working principle of Cam Followers mainly depends on the basic interaction between the cam and the roller and the rolling mechanism of the roller. By designing the profile of the cam and controlling the moving trajectory of the roller, accurate motion conversion and transmission control can be achieved. Reasonable structural design and material selection as well as appropriate lubrication and maintenance measures are also important factors to ensure the normal operation of Cam Followers.