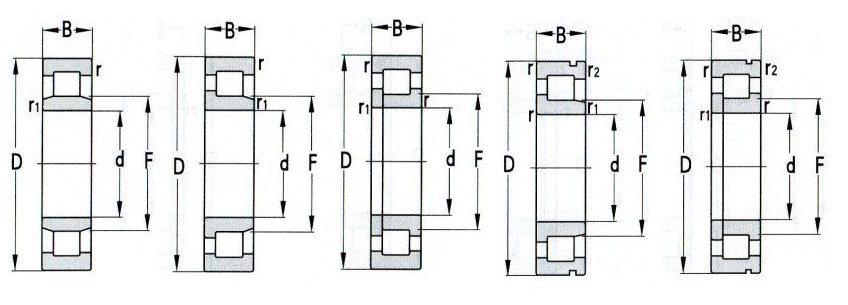

| Basic dimensions(mm) | Basic load rating(kN) | Limiting speed (r/min) | Bearing number | Weight kg |

||||||||

| d(mm) | D(mm) | B(mm) | rmin | r1min | r2min | F | Cr | Cor | Grease | Oil | ||

| 25 | 52 | 18 | 0.5 | 0.7 | 0.7 | 31 | 46.2 | 51.0 | 3500 | 6200 | NUP2205NV/C91YAD | 0.193 |

| 25 | 52 | 18 | 1 | 1.1 | - | 31 | 41.3 | 43.5 | 3500 | 6200 | NU2205V/C9YA6 | 0.176 |

| 25 | 52 | 18 | 1 | 0.3 | 0.7 | 31 | 47.9 | 48 | 3500 | 6200 | NUP2205NV/HAC9YA | 0.193 |

| 25 | 52 | 18 | 1 | 0.5 | 0.7 | 30.998 | 38.5 | 35 | 3500 | 6200 | NUP2205NV/HAC9Y | 0.173 |

| 25 | 62 | 20 | 3 | 1.1 | - | 34 | 59.4 | 60.5 | 2800 | 5000 | NJ305X2V/C3YA46 | 0.321 |

| 25 | 62 | 24 | 3 | 1.1 | - | 34 | 69.3 | 74.0 | 2200 | 4500 | NJ2305V/C3YA46 | 0.378 |

| 25 | 62 | 24 | 1.1 | 1.1 | - | 34.35 | 61.6 | 66.0 | 2200 | 4500 | NUP2305V | 0.401 |

| 30 | 62 | 19 | 1 | 2 | - | 38.2 | 51.7 | 58.5 | 3200 | 6000 | NCL2206X2V/YA6 | 0.272 |

| 30 | 72 | 19 | 2 | 2 | - | 40.4 | 80.0 | 60.5 | 1900 | 4000 | NU306EV/C9YA6 | 0.399 |

| 30 | 72 | 21 | 1.1 | 1.1 | - | 38.5 | 80.0 | 68.5 | 1900 | 4000 | NU306X2V/C3 | 0.431 |

| 30 | 72 | 30.162 | 1.5 | 1.0 | - | 60.409 | 275 | 445 | 1900 | 4000 | NCL3306X2V | 0.647 |

| 30 | 80 | 21 | 2.5 | 1.1 | - | 43.8 | 86.9 | 90.0 | 1900 | 4000 | NU306X3V | 0.565 |

| 35 | 80 | 21 | 1.5 | 1.1 | 0.5 | 46.2 | 103 | 89.0 | 2400 | 4800 | NJ307NV/C9 | 0.548 |

| 35 | 80 | 21 | 1.5 | 1.5 | 0.5 | 46.2 | 103 | 89.0 | 2400 | 4800 | NUP307NV/C9 | 0.579 |

| 35 | 80 | 21 | 1.5 | 1.1 | - | 46.2 | 103 | 89.0 | 2400 | 4800 | NJ307EV/C3 | 0.540 |

| 35 | 80 | 21 | 3 | 1.1 | - | 46.2 | 103 | 89.0 | 2400 | 4800 | NJ307EV/YA4 | 0.540 |

| 35 | 80 | 21 | 1.5 | 1.1 | - | 45.806 | 103 | 106 | 1500 | 3200 | NJ307EV/C9YAD | 0.537 |

| 35 | 80 | 23 | 3.5 | 1.1 | - | 45.8 | 103 | 48.0 | 2400 | 4800 | NJ607V | 0.568 |

| 35 | 82 | 23 | 1.1 | 0.3 | - | 64.5 | 79.0 | 112 | 1500 | 3200 | NFP2207X1V | 0.681 |

| 35 | 90 | 23 | 2 | 0.6 | - | 49.7 | 96.0 | 102 | 1500 | 3200 | NUP2207X1V/C9YB2 | 0.795 |

| 35 | 90 | 23 | 2 | 0.6 | - | 49.7 | 96.0 | 102 | 1500 | 3200 | NJ2207X1V/C9YB2 | 0.780 |

| 35 | 90 | 23 | 2.5 | 1 | - | 49 | 112 | 95.0 | 1500 | 3200 | NUP407X3V/C9YA6 | 0.75 |

| 35 | 90 | 23 | 5 | 1.5 | - | 48.5 | 112 | 83.5 | 1500 | 3200 | NCF407X3V/C9YA6 | 0.763 |

| 35 | 90 | 29 | 1.5 | 1.5 | 0.5 | 48 | 124 | 131 | 1500 | 3200 | NJ607NV | 0.998 |

| 40 | 90 | 23 | 1.1 | 1.1 | 0.5 | 53.44 | 140 | 110 | 1800 | 3600 | NUP308NV | 0.499 |

| 40 | 90 | 23 | 3.5 | 1.5 | - | 53.44 | 140 | 110 | 1800 | 3600 | NJ308V | 0.719 |

| 40 | 90 | 23 | 3.2 | 2 | - | 53.44 | 140 | 106 | 1800 | 3600 | NJ308V/C9YA6 | 0.719 |

| 40 | 90 | 23 | 3.5 | 1.5 | - | 52 | 140 | 95.5 | 1800 | 3600 | NJ308V/C3YA5 | 0.724 |

| 40 | 90 | 25 | 1.5 | 1.5 | - | 51 | 143 | 118 | 1200 | 2800 | NCF308X2V | 0.755 |

| 40 | 90 | 33 | 3.2 | 2 | - | 53.44 | 147 | 166 | 1000 | 2600 | NJ2308V/C9YA6 | 1.02 |

| 40 | 94 | 30 | 5 | 1.5 | - | 51.1 | 127 | 131 | 1000 | 2600 | NJ608V/YA13 | 1.02 |

| 45 | 100 | 25 | 1.5 | 1.5 | - | 57.85 | 136 | 127 | 1400 | 3000 | NJ309V | 0.904 |

| 45 | 100 | 25 | 1.5 | 2.2 | 0.5 | 57.3 | 118 | 126 | 1400 | 3000 | NUP309ENRV/C3YA6 | 1.02 |

| 45 | 100 | 31 | 4.5 | 1.5 | 0.5 | 56 | 165 | 153 | 1200 | 2800 | NJ2309X2NRV/C3YA6 | 1.21 |

| 50 | 80 | 28 | 1.1 | 0.6 | - | 58.5 | 94.5 | 177 | 1200 | 2800 | NU4010X2V/YAB | 0.575 |

| 50 | 110 | 27 | 2 | 2 | 0.5 | 66.72 | 160 | 156 | 1200 | 2800 | NUP310NV | 1.28 |

| 50 | 110 | 27 | 2 | 2 | - | 66.72 | 160 | 156 | 1200 | 2800 | NJ310V | 1.25 |

| 50 | 110 | 27 | 2 | 2 | 0.5 | 66.72 | 160 | 156 | 1200 | 2800 | NJ310V/HAC3YA6 | 1.25 |

| 50 | 110 | 27 | 2 | 2 | 0.5 | 66.72 | 160 | 156 | 1200 | 2800 | NUP310NRV/HAC3YA6 | 1.32 |

| 55 | 120 | 29 | 2 | 2 | 0.5 | 68.75 | 169 | 166 | 1100 | 2400 | NUP311NV | 1.63 |

| 55 | 120 | 29 | 2 | 2 | 0.5 | 68.75 | 169 | 166 | 1100 | 2400 | NUP311NRV | 1.69 |

| 56 | 160 | 60 | 2 | 2 | - | 77.15 | 300 | 360 | 1000 | 2200 | NUP6/56V | 7.29 |

| 60 | 130 | 62 | 1.5 | 1.5 | - | 81 | 230 | 385 | - | - | NUTR60130 | 4.74 |

| 65 | 140 | 33 | 2.1 | 2.1 | 0.5 | 82.7 | 212 | 249 | 1000 | 2000 | NUP313NV | 2.15 |

| 65 | 140 | 33 | 2.1 | 2.1 | 0.5 | 82.7 | 212 | 249 | 1000 | 2000 | NUP313NRV/HAC3YA6 | 2.59 |

| 65 | 140 | 33 | 2.1 | 2.1 | 0.5 | 82.7 | 212 | 249 | 1000 | 2000 | NUP313NRV/C3 | 2.59 |

| 70 | 150 | 35 | 2.1 | 2.1 | 0.5 | 90.97 | 320 | 272 | 900 | 1900 | NUP314NV/HA | 2.96 |

| 70 | 150 | 35 | 2.1 | 0.3 | 0.5 | 90.97 | 320 | 272 | 900 | 1900 | NUP314NV/YA6 | 2.96 |

| 85 | 120 | 22 | 1.1 | 1.1 | 1 | 83.1 | 98 | 170 | 1100 | 2400 | NCF2917V | 0.718 |

| 114.3 | 152.4 | 51.05 | 2 | 1.5 | - | 127.05 | 198 | 545 | 900 | 1900 | NCL6/114.3V/W33X | 2.81 |

| 150 | 210 | 36 | 2 | 2 | - | 163.5 | 303 | 540 | 670 | 1400 | NCF2930V | 3.89 |

| 220 | 300 | 48 | 2.1 | 1.5 | - | 282.4 | 550 | 985 | 4800 | 900 | NCF2944V | 9.63 |

| 240 | 320 | 48 | 2.1 | 2.1 | - | 285 | 550 | 1070 | 450 | 850 | NCF2948V | 10.2 |

| 260 | 320 | 28 | 2 | 1.1 | - | 127.5 | 270 | 550 | - | - | NCF1852V | 4.52 |

| 260 | 400 | 104 | 4 | 4 | - | 153 | 1570 | 2670 | 380 | 700 | NCF3052V | 44.1 |

| 280 | 380 | 60 | 2.1 | 2.1 | - | 340 | 825 | 1690 | 380 | 700 | NCF2956V | 19.8 |

| 300 | 420 | 72 | 3 | 3 | - | 390.5 | 1090 | 2155 | 340 | 630 | NCF2960V/C3 | 31.0 |

| 300 | 420 | 72 | 3 | 3 | - | 390.5 | 1240 | 2160 | 340 | 630 | NCF2960V/HC | 31.0 |

| 320 | 500 | 74 | 4 | 4 | - | 462 | 1420 | 2380 | 320 | 600 | NCF1064X1V | 52.4 |

| 340 | 460 | 72 | 3 | 3 | - | 367 | 1170 | 2420 | 320 | 600 | NCF2968V/C3 | 34.3 |

| 340 | 520 | 133 | 5 | 5 | - | 482 | 2300 | 4300 | 270 | 520 | NCF3068V/HC | 98.6 |

| 360 | 480 | 72 | 3 | 3 | - | 501 | 1180 | 2700 | 300 | 560 | NCF2972V | 36.5 |

| 380 | 480 | 46 | 2.1 | 1.5 | - | 520 | 650 | 1370 | 280 | 530 | NCF1876V | 17.0 |

| 380 | 480 | 56 | 2.1 | 1.5 | - | 534 | 840 | 1890 | 280 | 530 | NCF1876VY | 21.7 |

| 380 | 520 | 82 | 4 | 4 | - | 484.5 | 1480 | 3130 | 240 | 480 | NCF2976V | 52.9 |

| 400 | 540 | 82 | 4 | 4 | - | 511 | 1600 | 3400 | 220 | 460 | NCF2980V | 52.8 |

| 420 | 520 | 56 | 1.5 | 1.5 | - | 502 | 925 | 2220 | 240 | 480 | NCF1884VY | 25.7 |

| 420 | 560 | 82 | 4 | 4 | - | 542 | 1600 | 3650 | 240 | 480 | NCF2984V | 57.1 |

| 440 | 540 | 60 | 2.1 | 2.1 | - | 560 | 1020 | 2550 | 220 | 450 | FL-NCF2888V | 28.9 |

| 440 | 540 | 60 | 2.1 | 2.1 | - | 560 | 1020 | 2550 | 220 | 450 | FL-NCF2888V/HCE | 28.9 |

| 480 | 600 | 56 | 3 | 3 | - | 585 | 1060 | 2380 | 190 | 400 | NCF1896V | 32.6 |

| 480 | 600 | 76 | 3 | 3 | - | 572 | 1410 | 3430 | 190 | 400 | NCF1896VY | 45.2 |

| 500 | 670 | 100 | 5 | 5 | - | 670 | 2380 | 5300 | 170 | 360 | NCF29/500V | 97.7 |

| 530 | 650 | 56 | 3 | 3 | - | 720 | 1020 | 2320 | 180 | 380 | FL-NCF18/530V | 33.9 |

| 530 | 650 | 56 | 3 | 3 | - | 720 | 1020 | 2320 | 180 | 380 | FL-NCF18/530V/HCE | 33.9 |

| 560 | 750 | 190 | 5 | 5 | - | 980 | 3030 | 6700 | 150 | 320 | NCF29/560V | 134 |

| 560 | 820 | 195 | 6 | 6 | - | 980 | 5500 | 11500 | 150 | 320 | NCF30/560V/HC | 336 |

| 600 | 800 | 118 | 5 | 5 | - | 953 | 3100 | 700 | 140 | 300 | NCF29/600V | 163 |

| 630 | 850 | 128 | 6 | 6 | - | 980 | 3500 | 7560 | 130 | 280 | NCF29/630V | 201 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V/HCE | 72.2 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V | 72.2 |

| 670 | 900 | 136 | 6 | 6 | - | 1024 | 4000 | 9500 | 120 | 260 | NCF29/670V | 245 |

| 630 | 850 | 128 | 6 | 6 | - | 980 | 3500 | 7560 | 130 | 280 | NCF29/630V | 201 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V/HCE | 72.2 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V | 72.2 |

| 670 | 900 | 136 | 6 | 6 | - | 1024 | 4000 | 9500 | 120 | 260 | NCF29/670V | 245 |

| 630 | 850 | 128 | 6 | 6 | - | 980 | 3500 | 7560 | 130 | 280 | NCF29/630V | 201 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V/HCE | 72.2 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V | 72.2 |

| 670 | 900 | 136 | 6 | 6 | - | 1024 | 4000 | 9500 | 120 | 260 | NCF29/670V | 245 |

| 630 | 850 | 128 | 6 | 6 | - | 980 | 3500 | 7560 | 130 | 280 | NCF29/630V | 201 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V/HCE | 72.2 |

| 670 | 820 | 69 | 4 | 4 | - | 1012 | 1320 | 3230 | 130 | 280 | FL-NCF18/670V | 72.2 |

| 670 | 900 | 136 | 6 | 6 | - | 1024 | 4000 | 9500 | 120 | 260 | NCF29/670V | 245 |

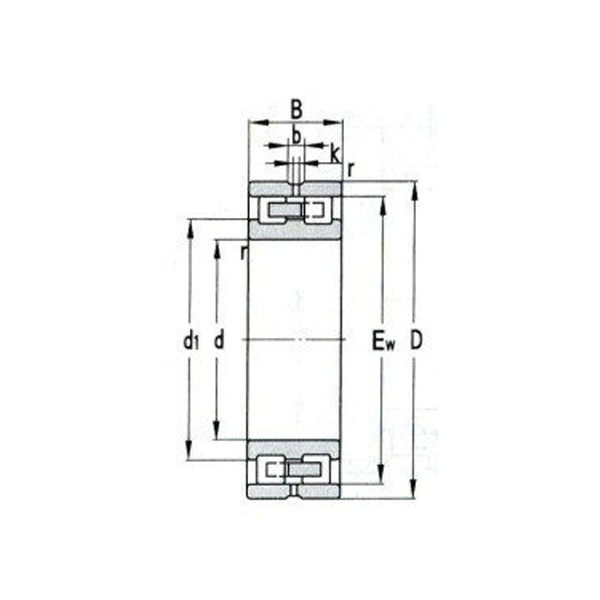

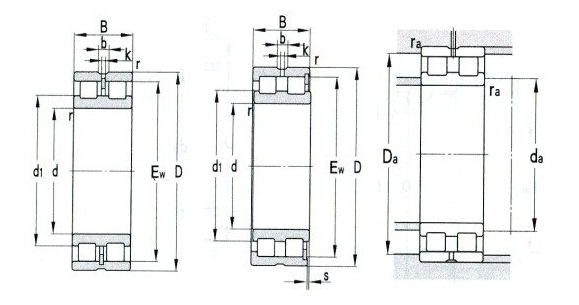

| Basic dimensions (mm) |

Basic load rating (KN) |

Limiting speed (r/min) |

Bearing number | Other dimensions mm | Abutment and fillet dimensions mm |

Weight kg |

|||||||||||

| d | D | B | r | Ew.Fw | Cr | Cor | Grease | Oil | d1 | D1 | b | k | da(min) | Da(max) | ra(max) | ||

| 40 | 68 | 38 | 0.6 | 60.8 | 86.0 | 129 | 2000 | - | NNF5008V | 50.3 | - | - | - | 44 | 63 | 0.6 | 0.553 |

| 40 | 68 | 38 | 0.6 | 60.8 | 86.0 | 129 | 2000 | - | NNF5008-2LSV | 50.3 | - | - | - | 44 | 63 | 0.6 | 0.553 |

| 40 | 68 | 38 | 1.0 | 60.8 | 86.0 | 129 | 2000 | - | NNCF5008V | 50.3 | 57.3 | 7 | 3 | 44 | 63 | 1.0 | 0.553 |

| 56 | 160 | 60 | 1.5 | - | 275 | 380 | - | - | NUTR56160 | 62 | - | - | - | 60 | 145 | 1.2 | 7.87 |

| 56 | 160 | 63 | 5 | - | 275 | 380 | - | - | NUTR56160/YA7 | 62 | - | - | - | 60 | 145 | 1.2 | 7.76 |

| 65 | 150 | 52 | 2.0 | - | 235 | 375 | - | - | NUTR65150 | 72 | - | - | - | 70 | 138 | 1.0 | 5.26 |

| 70 | 110 | 54 | 0.6 | 100 | 190 | 325 | 1200 | - | NNF5014-2LSNV | 85 | - | - | - | 75 | 105 | 0.6 | 1.85 |

| 80 | 190 | 75 | 1.5 | - | 240 | 390 | - | - | NUTR616-2RS/C9 | 91 | - | - | - | 87 | 183 | 1.0 | 13.2 |

| 80 | 190 | 75 | 1.5 | - | 240 | 390 | - | - | NUTR616-2RS/C9YAD | 91 | - | - | - | 87 | 183 | 1.0 | 18 |

| 85 | 130 | 60 | 1.1 | 121.4 | 308 | 510 | 1100 | 2400 | NNCF5017V/W33 | 99.5 | - | 4 | 2 | 91.5 | 123.5 | 1.0 | 2.73 |

| 89 | 125 | 58 | 1.1 | 97.22 | 191 | 375 | 1100 | 2400 | NUCL6/89V/YA3DF | - | 111.6 | - | - | 96.5 | 118.5 | 1.0 | 1.87 |

| 90 | 125 | 58 | 1.1 | 97.22 | 191 | 375 | 1000 | 2200 | NUCL3918X2V/YA3DF | - | 111.6 | - | - | 106.5 | 114 | 1.0 | 1.81 |

| 90 | 140 | 67 | 1.5 | 130 | 385 | 660 | 900 | 1900 | NNCF5018V | 106.5 | - | - | - | 106.5 | 133.5 | 1.0 | 3.68 |

| 100 | 150 | 67 | 1.0 | 138 | 320 | 590 | 850 | - | NNF5020-2RSV | 118 | - | - | - | 106 | 145 | 1.0 | 3.99 |

| 110 | 170 | 80 | 2.0 | 154.5 | 400 | 805 | 750 | 1900 | NNCF5022V | 130 | - | - | - | 116.5 | 164 | 1.0 | 6.49 |

| 110 | 170 | 80 | 1.5 | 154 | 380 | 790 | 750 | - | NNF5022-2LSV | 131 | - | - | - | 117 | 165 | 1.5 | 6.93 |

| 110 | 260 | 110 | 1 | 132 | 1010 | 1500 | 700 | 1500 | NNFPL2422X3V/HAP59 | - | 184 | - | - | 116.5 | 238 | 1 | 34 |

| 120 | 180 | 80 | 0.6 | 164 | 445 | 885 | 700 | - | NNF5024-2LSNV | 141 | - | - | - | 127 | 175 | 0.6 | 7.41 |

| 130 | 200 | 94 | 1.0 | 185.2 | 540 | 1000 | 680 | - | NNF5026-2LSNRV | 158 | - | - | - | 137 | 195 | 1.0 | 11.1 |

| 140 | 210 | 95 | 2.0 | 195.5 | 700 | 1380 | 650 | - | NNCF5028V | 164.5 | 188.9 | - | - | 147 | 205 | 2.0 | 11.3 |

| 160 | 220 | 60 | 2.0 | - | 405 | 935 | - | - | NNF4932V | 191 | - | - | - | 167 | 235 | 1.0 | 7.08 |

| 160 | 240 | 109 | 0.6 | 222.6 | 835 | 1680 | 630 | 1300 | NNF5032-2LSNRV | 191 | - | - | - | 167 | 235 | 0.6 | 18.8 |

| 160 | 240 | 109 | 1.1 | 222.6 | 835 | 1680 | 630 | - | NNF5032-2LSNRV/YB2 | 191 | - | - | - | 167 | 235 | 1.0 | 18.4 |

| 170 | 260 | 122 | 2.1 | 239 | 1010 | 1060 | 2120 | - | NNCF5034V | - | - | - | - | 177 | 255 | 0.6 | 21.4 |

| 170 | 260 | 122 | 2.1 | 239 | 1010 | 1060 | 2120 | - | FL-NNCF5034V/C3 | - | - | - | - | 177 | 255 | 0.6 | 21.4 |

| 170 | 260 | 122 | 0.6 | 239 | 1010 | 1990 | 580 | - | NNF5034-2RSV | - | - | - | - | 177 | 255 | 0.6 | 23.5 |

| 170 | 260 | 122 | 0.6 | 239 | 1010 | 1990 | 580 | - | NNF5034-2RSNV | - | - | - | - | 177 | 255 | 0.6 | 23.5 |

| 180 | 250 | 69 | 2 | - | 580 | 1310 | - | - | NNCL4936V | - | - | - | - | 191 | 269 | 2.0 | 10.4 |

| 180 | 280 | 74 | 2.1 | - | 790 | 1420 | 450 | - | NCF3036V | - | - | - | - | 191 | 269 | 2.0 | 16.9 |

| 180 | 280 | 135 | 0.6 | 254 | 1140 | 2380 | 560 | 1100 | NNF5036-2LSNRV | - | - | - | - | 191 | 269 | 0.6 | 33.3 |

| 180 | 280 | 135 | 2.1 | 254 | 1140 | 2380 | 560 | - | NNF5036-2LSV | - | - | - | - | 191 | 269 | 2.0 | 32.5 |

| 200 | 280 | 48 | 2.1 | - | 455 | 895 | - | - | NCF2940V | - | - | - | - | 191 | 269 | 2.0 | 8.91 |

| 220 | 330 | 80 | 2.1 | 276.8 | 695 | 1620 | 500 | 950 | NNCF4944V/C3 | - | - | - | - | 231 | 319 | 2.0 | 16.8 |

| 240 | 320 | 80 | 2.1 | 299.8 | 765 | 1880 | 450 | 850 | NNC4948V/C3 | - | - | - | - | 251 | 309 | 2.0 | 18.3 |

| 240 | 360 | 159 | 1 | - | 1580 | 3850 | 340 | - | NNF5048-2LSNRV | - | - | - | - | 251 | 346 | 2.0 | 60.7 |

| 260 | 400 | 190 | 4 | - | 2750 | 5500 | - | - | NNCF5052V | - | - | - | - | 272 | 383 | 2.0 | 83.9 |

| 260 | 400 | 189 | 1.1 | - | 2180 | 4800 | - | - | NNF5052-2LSNRV | - | - | - | - | 272 | 383 | 2.0 | 92.4 |

| 300 | 420 | 118 | 3.0 | 390.2 | 1460 | 3300 | 340 | 630 | NNCF4960V/C3 | - | - | - | - | 314 | 406 | 2.5 | 49.3 |

| 380 | 540 | 260 | 4.0 | 508 | 4000 | 8000 | 120 | 260 | NNCL5076X3V/HCC9T | - | - | - | - | 396 | 524 | 3.0 | 154 |

| 400 | 600 | 272 | 5.0 | - | 5700 | 11700 | - | - | NNCL5080V/HC | - | - | - | - | 411 | 588 | 3.0 | 266 |

| 420 | 520 | 100 | 2.1 | 493 | 2090 | 4200 | 220 | 450 | NNCL4884V/C9W33X | 10 | - | 10 | 8 | 428 | 509 | 2.0 | 48.4 |

| 460 | 580 | 118 | 3.0 | 544 | 2870 | 5500 | 220 | 450 | NNCS4892V/W33 | 20.5 | - | 20.5 | 12 | 474 | 560 | 2.5 | 75.5 |

| 480 | 600 | 118 | 3.0 | 567 | 3100 | 5750 | 200 | 430 | NNCS4896V/W33 | 20.5 | - | 20.5 | 12 | 500 | 588 | 2.5 | 78.4 |

| 560 | 820 | 400 | 6.0 | 771 | 8300 | 19600 | 150 | 300 | NNCL50/560X2V/HCC9T | - | - | - | - | 590 | 790 | 5.0 | 578 |

| 600 | 870 | 272 | 6.0 | - | 6970 | 17000 | - | - | NNCL40/600V/HC | - | - | - | - | 612 | 853 | 3.0 | 509 |

Search

Search EN

EN English

English Español

Español